Our Company

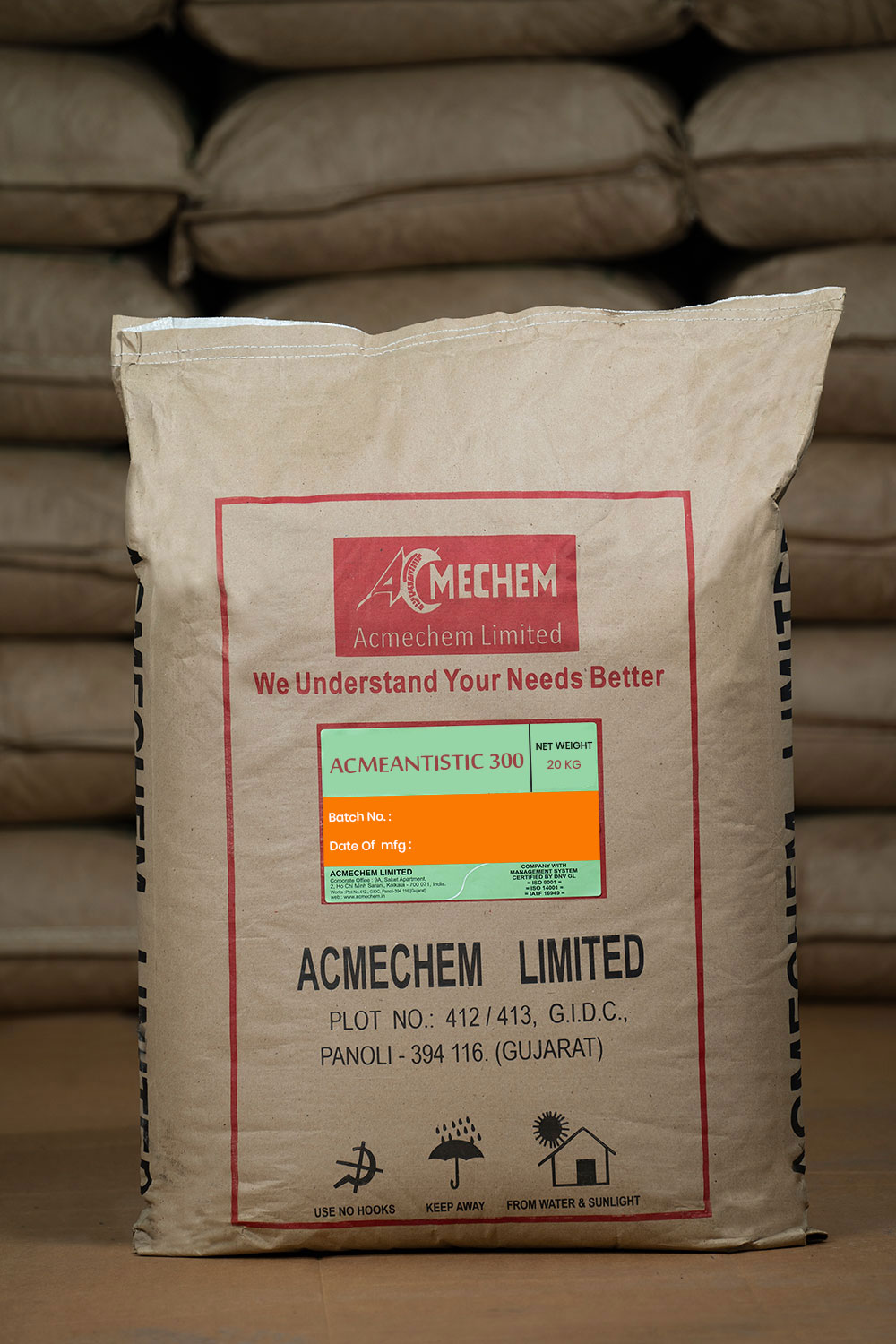

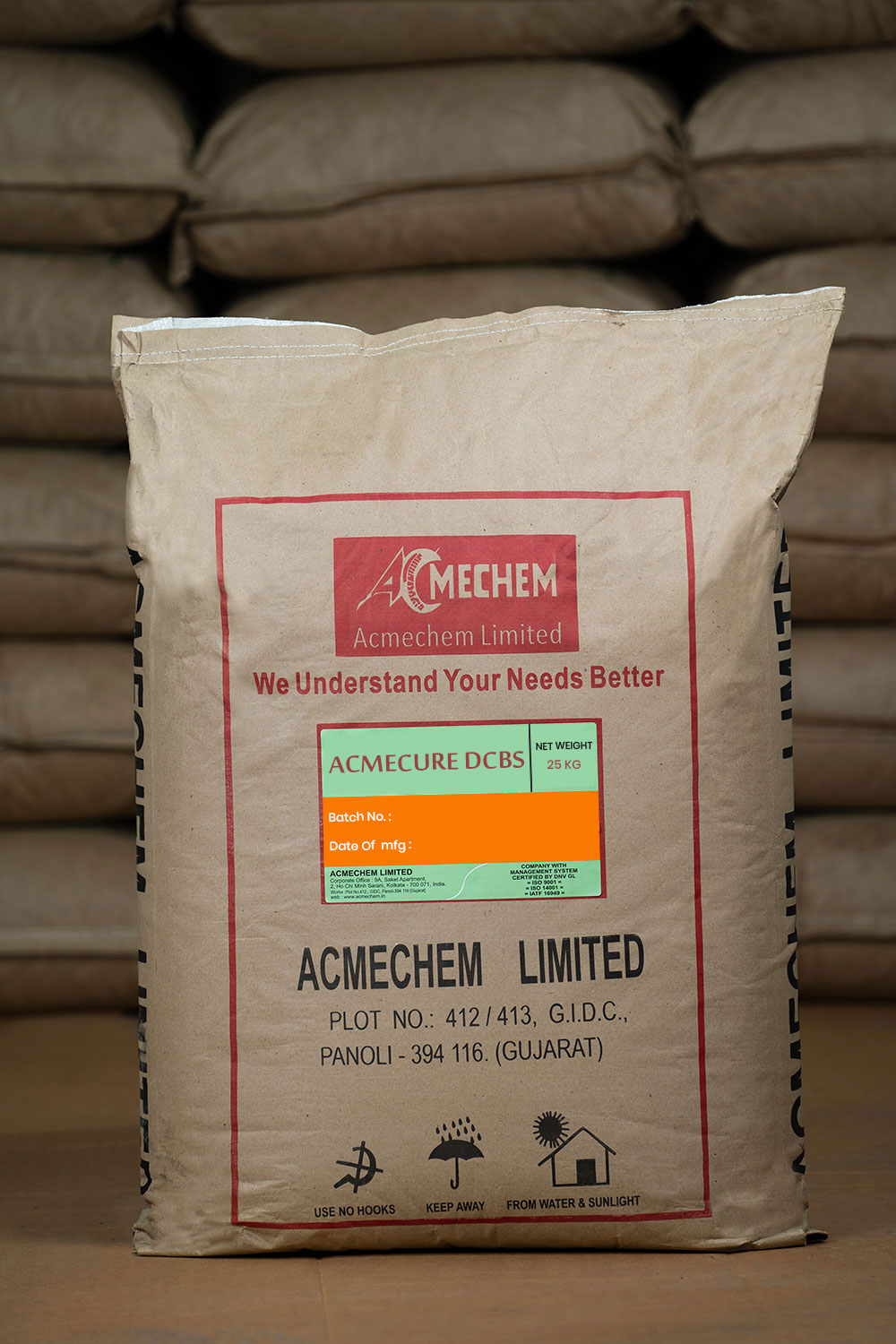

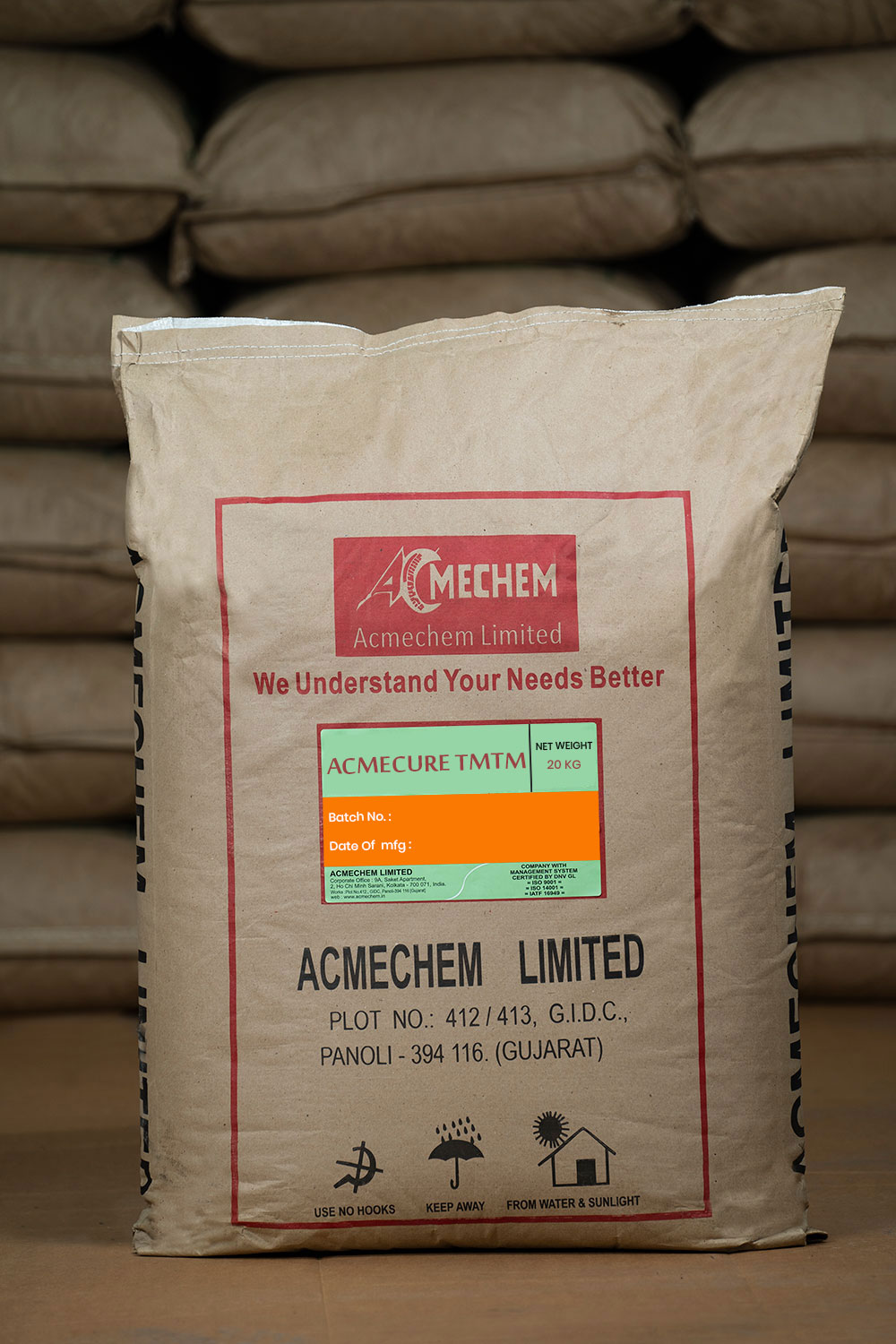

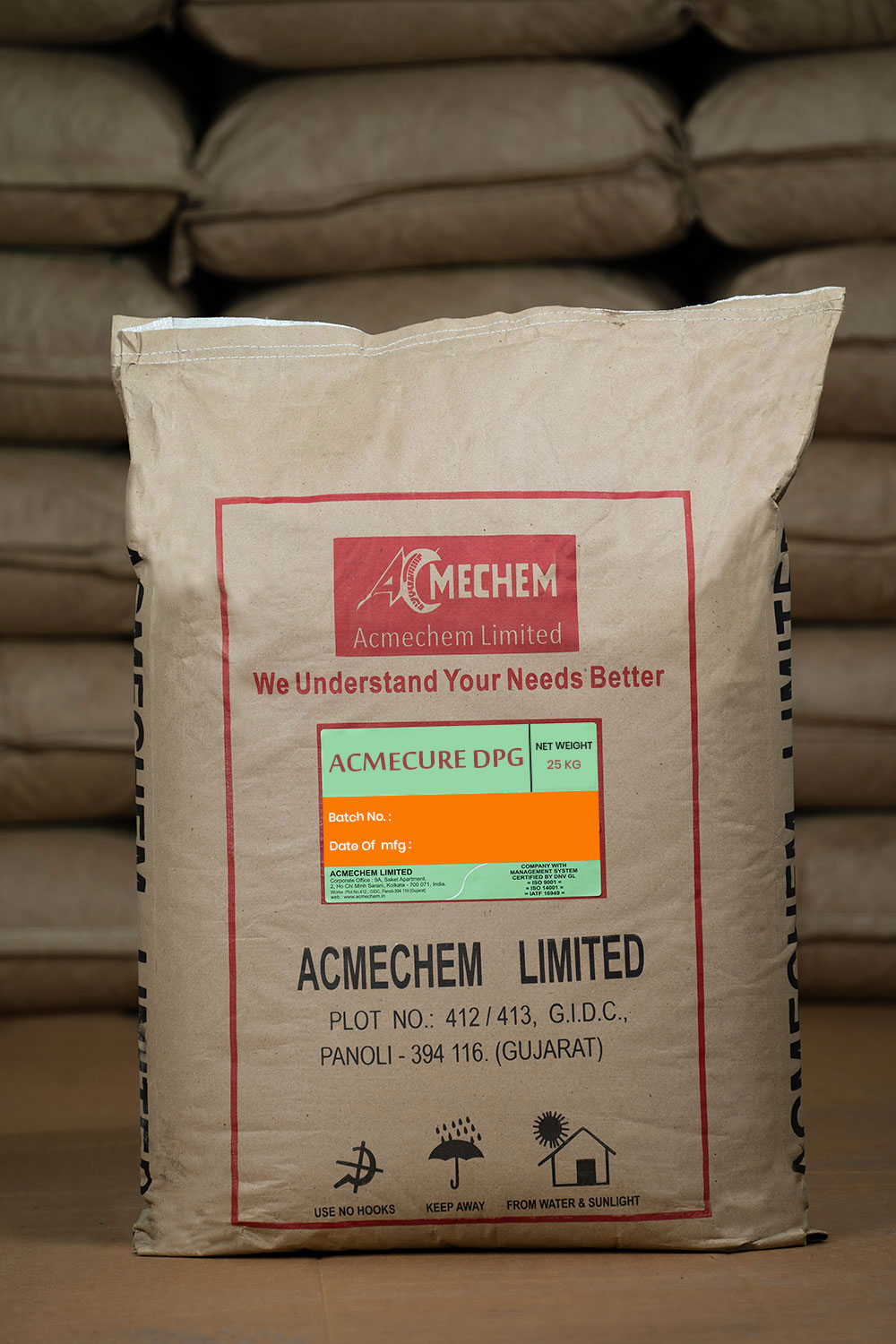

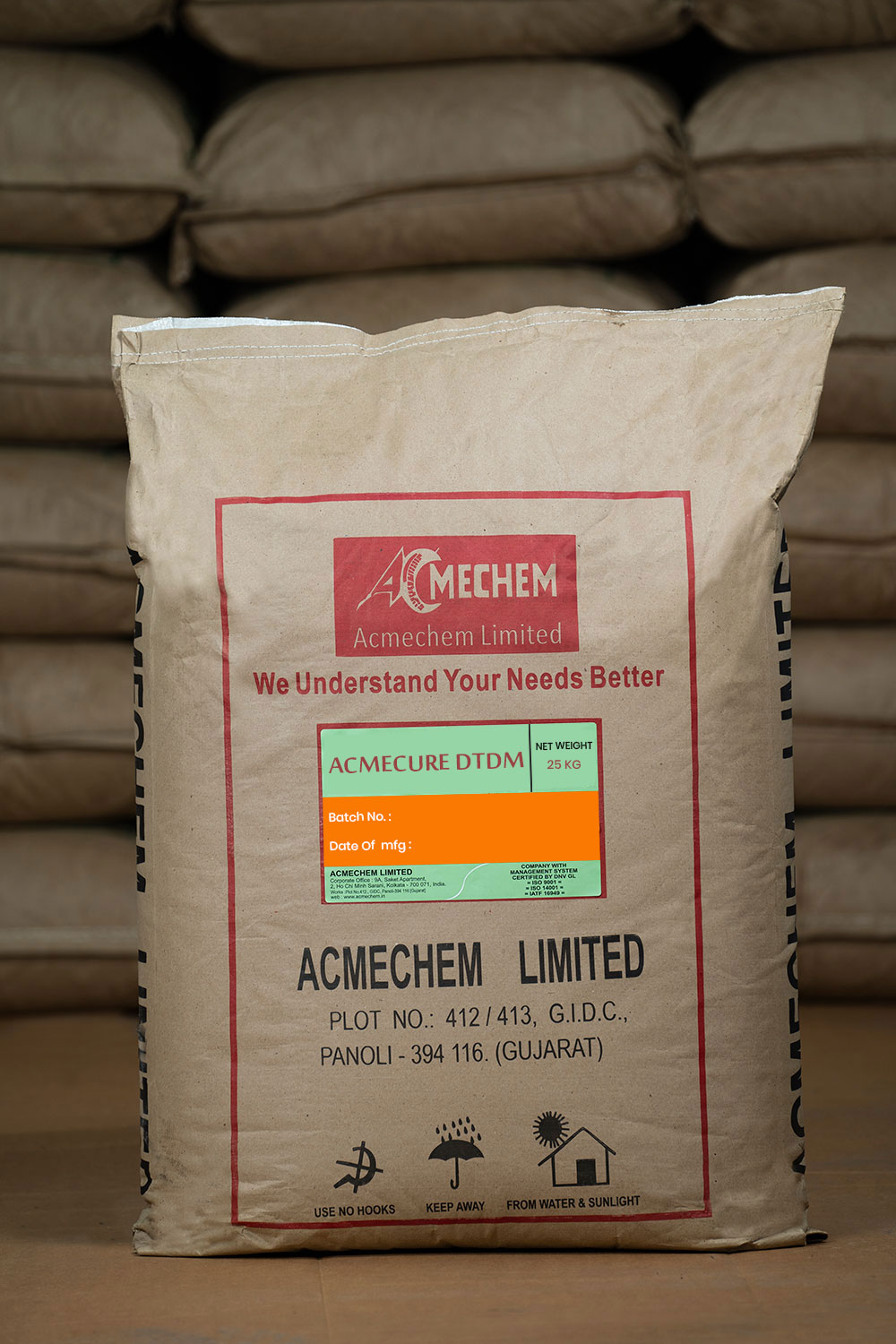

Acmechem, founded in early nineties has established itself as a quality manufacturer of Fine and Performance Chemicals for the Rubber Industry. The company takes pride in developing close links with all its customers. The company has developed a reputation in India as a reliable and successful business partner and is a leader in the adoption and implementation of quality, environmental and regulatory standards.

.jpg)

.jpg)

.jpg)

.jpg)